The Evolution of Digital Twins: Virtual Models

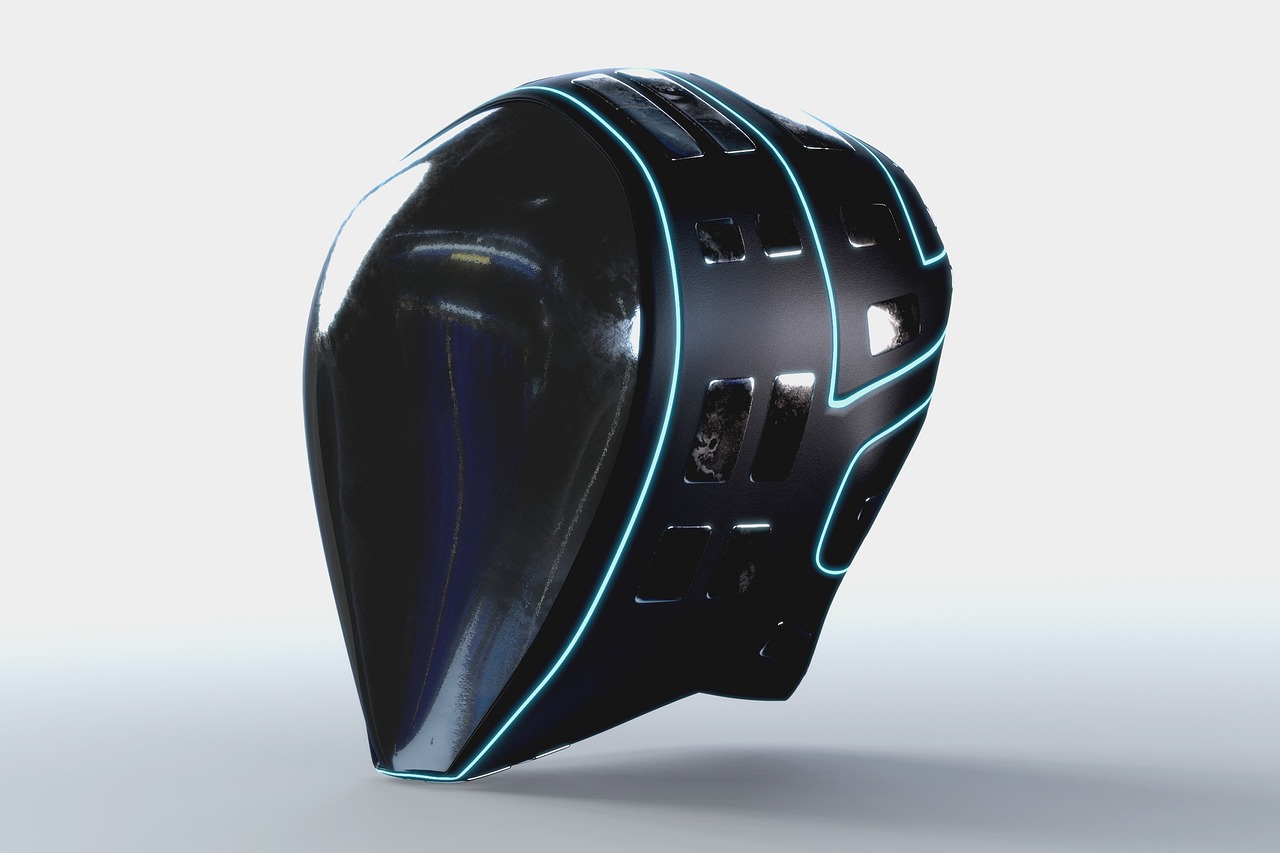

Digital twins are virtual representations of physical objects or systems that exist in the digital world. They are created using real-time data from sensors embedded in the physical objects. These virtual replicas enable real-time monitoring, analysis, and simulation of the physical objects or systems, providing insights and predictions for better decision-making.

By replicating the physical objects or systems in a digital environment, digital twins help in optimizing performance, improving efficiency, and minimizing downtime. The concept of digital twins is increasingly being adopted across various industries to enhance product development, monitor equipment health, and optimize processes.

• Digital twins are virtual representations of physical objects or systems in the digital world

• They are created using real-time data from sensors embedded in the physical objects

• Digital twins enable real-time monitoring, analysis, and simulation of physical objects or systems

• They provide insights and predictions for better decision-making

• By replicating physical objects or systems in a digital environment, digital twins help optimize performance and improve efficiency

• The concept of digital twins is being adopted across various industries to enhance product development, monitor equipment health, and optimize processes

History of Digital Twins

Digital twins have become a prominent concept in the realm of technology, but their origins can be traced back to the early 2000s. The term “digital twin” was first coined by Dr. Michael Grieves at the University of Michigan, referring to a virtual representation of a physical object or system.

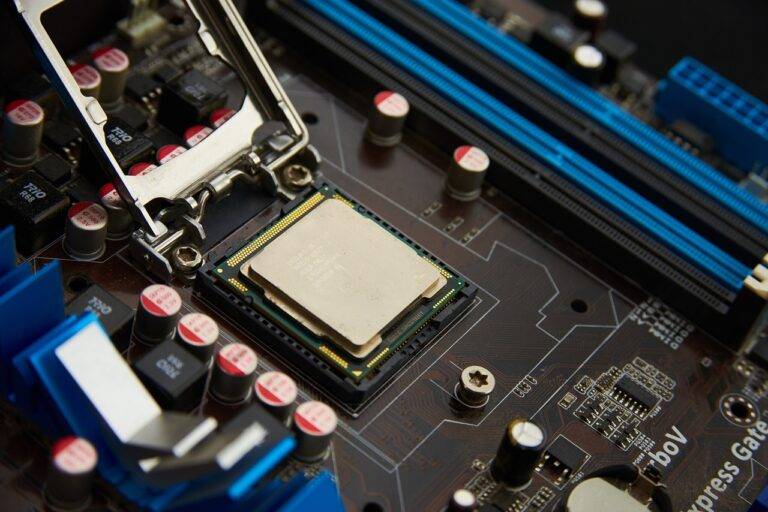

Initially used in the manufacturing industry, digital twins were primarily employed to monitor and optimize the performance of machines and equipment. Over time, their utility expanded beyond manufacturing into various sectors, including healthcare, automotive, and aerospace. The concept gained momentum with the advancement of internet of things (IoT) technologies, allowing real-time data to be integrated with digital replicas for enhanced analysis and decision-making.

Applications of Digital Twins in Various Industries

Digital twins have found widespread applications across a multitude of industries, revolutionizing the way processes are managed and optimized. In the aerospace sector, digital twins are utilized to enhance aircraft performance, monitor maintenance schedules, and predict potential failures before they occur, ensuring the safety and efficiency of flights. By creating digital replicas of aircraft components and systems, engineers can analyze real-time data to make informed decisions and streamline operations.

In the healthcare industry, digital twins play a vital role in personalized medicine and patient care. By creating virtual models of individual patients, healthcare professionals can simulate various treatment scenarios, predict outcomes, and tailor treatments based on specific genetic markers and lifestyle factors. This technology enables medical practitioners to offer more precise diagnoses, improve treatment efficiency, and ultimately enhance patient outcomes.

What is the definition of Digital Twins?

Digital Twins are virtual replicas of physical objects, processes, or systems that allow for real-time monitoring, analysis, and simulation.

Can you provide a brief history of Digital Twins?

Digital Twins have been around since the early 2000s but have gained popularity in recent years with advancements in technology such as IoT, AI, and Big Data.

In which industries are Digital Twins commonly used?

Digital Twins are used in a wide range of industries including manufacturing, healthcare, aerospace, automotive, and smart cities.

How do Digital Twins benefit the manufacturing industry?

In manufacturing, Digital Twins can help optimize production processes, predict maintenance issues, and improve overall efficiency.

What are some applications of Digital Twins in healthcare?

In healthcare, Digital Twins can be used to create personalized treatment plans, simulate surgical procedures, and monitor patient health in real-time.

How are Digital Twins utilized in the aerospace industry?

In aerospace, Digital Twins are used to monitor aircraft performance, predict maintenance needs, and simulate different flight scenarios.

How do Digital Twins impact the automotive industry?

In the automotive industry, Digital Twins can help manufacturers design and test new vehicles, optimize supply chains, and improve vehicle performance.

What role do Digital Twins play in smart cities?

In smart cities, Digital Twins can be used to monitor and optimize energy usage, traffic flow, and public services to improve overall quality of life.